We are the biggest Manufacturer, Suppliers and Exporter of Exothermic Weld Powder and its Accessories.

Exothermic Welding Connection is a way to connect the ground core with grounding, copper wires to copper wires. Copper wire with ground rod, Steel, copper, etc., with the high-efficiency heat used to connect grounding in the ground. This is a convenient and efficient process. Good connection The welding points are good for shock absorption and The cost of connection is relatively low when Compared to other welding processes such as gas welding welding, welding, exothermic welding, the two types of heat to be bonded . The heat is too high to melt. Both types of metal are heated. By spotting the powder, welding with a spark to ignite. Quickly do it together and coordinate with. Quick Exothermic welding powder, rapid heating The advantages of this type of welding due to heat <a I = 17> happens very quickly, it makes welding possible. Different melting points (different metals, for example. Welding steel and copper) well due to heat Immediate, no heating Continuously, the molten metal melts first. Welding procedure Before welding, the metal must be cleaned.

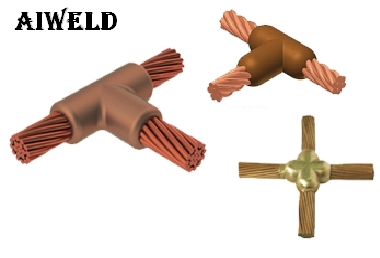

Exothermic weld is also known as Exothermic bonding. There are many advantages of using exothermic weld. The most important one of exothermic weld is being that the process produces a molecular joint and not just a mechanical one in between the conductors. Exothermic weld is produced through a starting reactant which provides enough energy to activate the weld reaction. This takes place quickly and safely inside a graphite mold. The mold is designed specifically for a certain union depending on the elements to be welded and the joint type required. We guarantee all types of joints, not only copper cable unions but also to weld tapes, brass metallic pieces, stainless steel, steel ground rods covered with copper, etc. It is especially useful for joining dissimilar metals.

Features of Exothermic Weld:

- Superior electrical conductivity to the conductors themselves.

- Does not corrode, oxidize or degrade with time and is resistant to galvanic coupling.

- Able to withstand repeated electrical discharges.

- Never increases its resistance.

- Has greater mechanical and squeezing resistance than the conductors themselves.

- It has Superior electrical conductivity to the conductors themselves.

- It does not corrode, oxidize or degrade with time and is resistant to galvanic coupling.

- It is able to withstand repeated electrical discharges.

- It never increases its resistance.

- It has greater mechanical and squeezing resistance than the conductors themselves.

- It Offers a permanent weld and a low resistance connection, essential for achieving long wearing and trustworthy results in earthing.

- It Guarantees the most common connections not only between copper cables but also for welding tapes and metallic pieces made of brass, stainless steel, and copper coated steel earth rods.

The exothermic weld process is a simple, self- contained method of forming high quality electrical connections. The compact process requires no external power or heat source, making it completely portable. Connections are made inside a semi-permanent graphite mould using the high temperature reaction of powdered copper oxide and aluminium.

The Exothermic Weld Powder is copper base will be melted to complete the metallic bond at least 2 metals or conductors connection. The good powder will give the smooth and colorful joint.

An Exothermic Weld Connection is actually a molecular bond formed between two metals such as

copper/copper, copper/steel and steel/steel.

Copper oxide and aluminium are combined and ignited.

Exothermic Weld Powder is packed in plastic cartridge with difference size (weight in gram) according to the connection needed. Each cartridge consistes of welding powder 97% by weight, and the starting powder at the bottom of the cartridge.

We are the distribution of Exothermic Weld Copper Powder, Graphite Mold, the mold used in Exothermic Weld Connection, Day Times ceramic, trap seal, Earth / Ground Rod and ground transportation system on the cheap quality, fast delivery. We also have a team of installation.And the electrical system ground. , Industrial, machine installation. With a team of experienced directly.

Exothermic Weld Powder consists of copper oxide and aluminum which is measure into specific weight in grams for the connections should be made approximatly 97 % of the contents of this cartridge is the weld metal, the remaining part is a starting powder which is tamped into the bottom of the each cartridge.

Weld metals consist of copper oxide, aluminium and flux in powder form. The powders are packed into plastic containers and the quantity is pre-determined by the factory for specific connections. The Exothermic weld powders are marked in sizes, e.g. 15, 25, 32, 45, 65, 75, 90, 115, 150, 200 and 250g.

The Exothermic Weld Powder is packed under the white cap of the container and the ignition powder is packed under the red cap.

The ignition temperature of the weld metal powder is approximately 1000°C. This high ignition temperature is difficult to achieve hence we use an ignition powder to start the reaction.

This ignition powder is similar to the weld metal with the exception that it is much finer, allowing ignition at about 450°C by using a flint gun (igniter). This cannot be ignited with a normal flame ie. matches, cigarette light etc.

Under no circumstances must half the quantity of weld metal stipulated be used and neither must the quantity be doubled up. Each quantity is for a specific type of connection only.

Should any fault be experienced with the powder, the batch number on the AIWELD® leaflet must be referred to when logging the complaint, as without it no reference can be done.

The result is an Exothermic Reaction that produces molten super-heated copper and aluminium oxide slag.

The melting or fusing temperature rating of the finished joint is 2000°C plus. The molten super-heated copper melts the objects being connected together, forming the molecular bond.

This bond will not loosen over time or deteriorate with age. The connection’s current carrying capability is to that which it is being connected. In other words there is no increase in resistance in an exothermically welded connection as there is in most pressure connections.

The majority of exothermic weld connections have at least twice the cross sectional area of the conductors being joined, and an equivalent or greater current carrying capacity. Because the connection is a fusion of high conductivity, high copper content alloy, it will withstand repeated fault currents, and will not loosen in the way that mechanical connections can.